- +86 020 2902 6603

- +86 18826241798

- oversea@pearlelectric.com

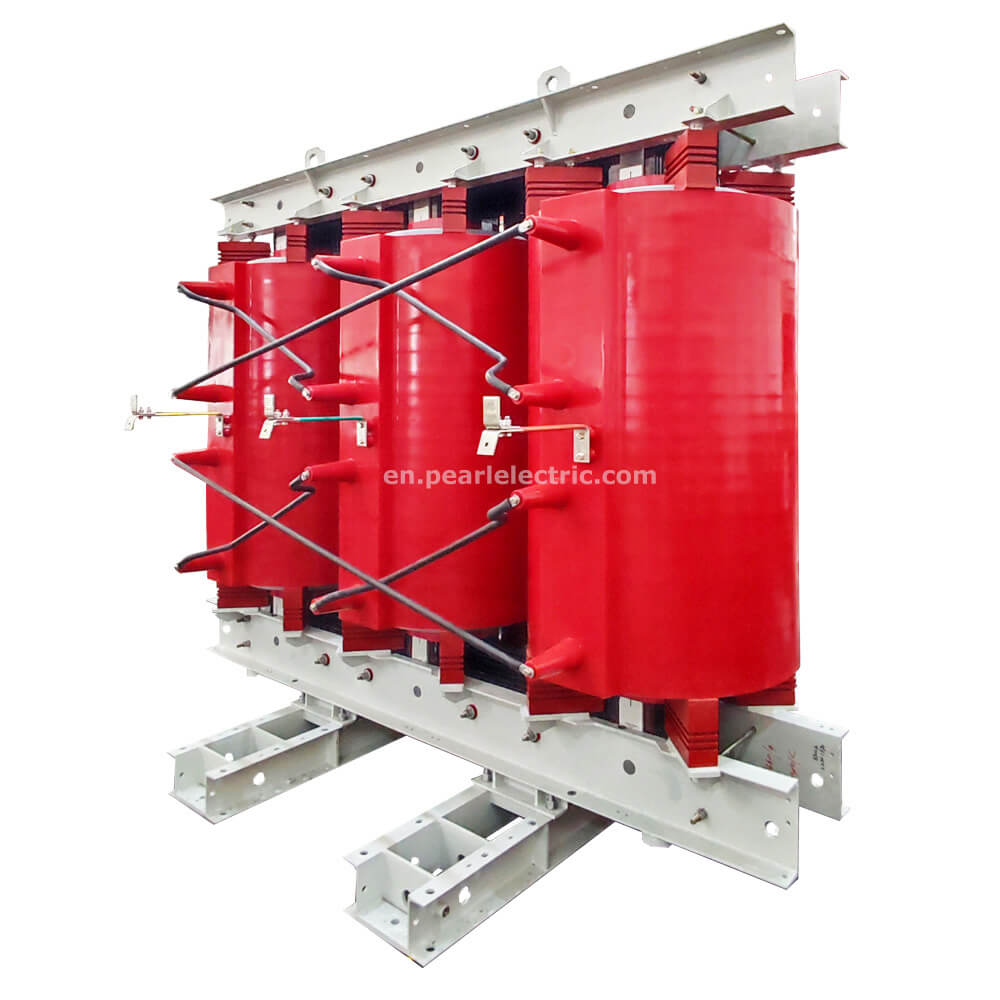

Type: Cast Resin Dry Type Transformer

Rated Power Capacity: 3300kVA

Primary Voltage: 33kV

Secondary Voltage: 0.44kV

Frequency: 50Hz

Phase: 3 phases

Vector group: Dyn11

The cast resin dry type series transformer is the kind of the transformer with low noise, low loss and low partial discharge. With rational structure, high-quality material, scientific design,strict craftmanship and advanced test method, the characteristics of this series products are as follows:

Ø Flameproof and no blast, no pollution, no venomous gas.

Ø High dampproot, Safe operation in 100% vilative humidity and other tough enviroment, no demoisture procedure is needed.

Ø Strong capacity of heart resistant.

Ø High over-load capacity, running at 110% rated load, and 150% rated load at AF.

Ø Contour artistic and compact size, low cost for installing.

Ø Performance and parameter conform to or excel the standards of GB, IEC or industry.

Detailed Specification:

Rated Capacity | 3300 kVA |

Rated Voltage(HV/LV) | 33/1.8 kV |

Frequency | 50 Hz |

Winding Material | Copper |

Core Materials | Silicon Steel |

Insulation Level | as Per IEC Standard |

Class of Protective Enclosure | 15 |

IP CODE(T/H/L) | IP54/IP54/IP54 |

Lightning Impulse Withstand Voltage | as Per IEC Standard |

Process Technology:

Core:

Ø Our transformer’s core is made of high quality cold rolled grain oriented silicon steel sheet with high magnetic permeability. It is using full 45° slope lamination, so that the no-load loss and the no-load current are reduced efficiently.

Ø We use Simulating Analysis in the core model design, so that we can calculate the frequency and size of the vibration exactly and avoid the core cavity resonance.

Ø Between core & windings, and core & frame, we use spring connection. Then the noise is lower 10 to 15dB than the standard.

LV Winding:

Ø LV windings, above 400 kVA capacity, are adopting superior foil conductors, thus to obtain better amper-turn balance and reduce more transverse magnetic flux leakage. Then to greatly improves transformer's anti-short circuit capability.

Ø The wise design of air passage within the winding, greatly increasing the winding's heat dispersion effect. It helps to decrease temperature rise and improve products' overload capability.

HV Winding

Ø HV windings are made of superior copper-conductor wires. Adopting fiberglass to reinforced insulation.

Ø The HV windings are casting under vacuum and high pressure conditions with Germany HUBERS vacuum Cast Machine. In this way, transformer's resin can get the best penetration. It can also greatly reduce its partial discharge (partial discharge for 11kV product could be lower than 5pC).

Ø HV windings are adopted optimized structure to improve transformer's distribution of electric field.

Ø We use our existing technology calculate and analysis Lightning wave process simulation. Then substantially improving product's anti-lighting capability.

Advantage:

Ø Low loss, low noise, low partial discharge, high reliability

Ø Powerful anti-short circuit capacity, high anti-lightning impulse capacity

Ø HV coil is Vacuum casted with epoxy resin with pressure, capabilities for better the cast without pressure.

Ø Simulating analys is being used in the core model, the resonance can be avoided and the noise is reduced.

Ø Simulation calculation and analysis of lightning impulse wave are applied to HV Coils; anti-lightning impulse capability is improved.

the professional team to service !